#15 - Infrared Curing Technology

Cooler months are coming!

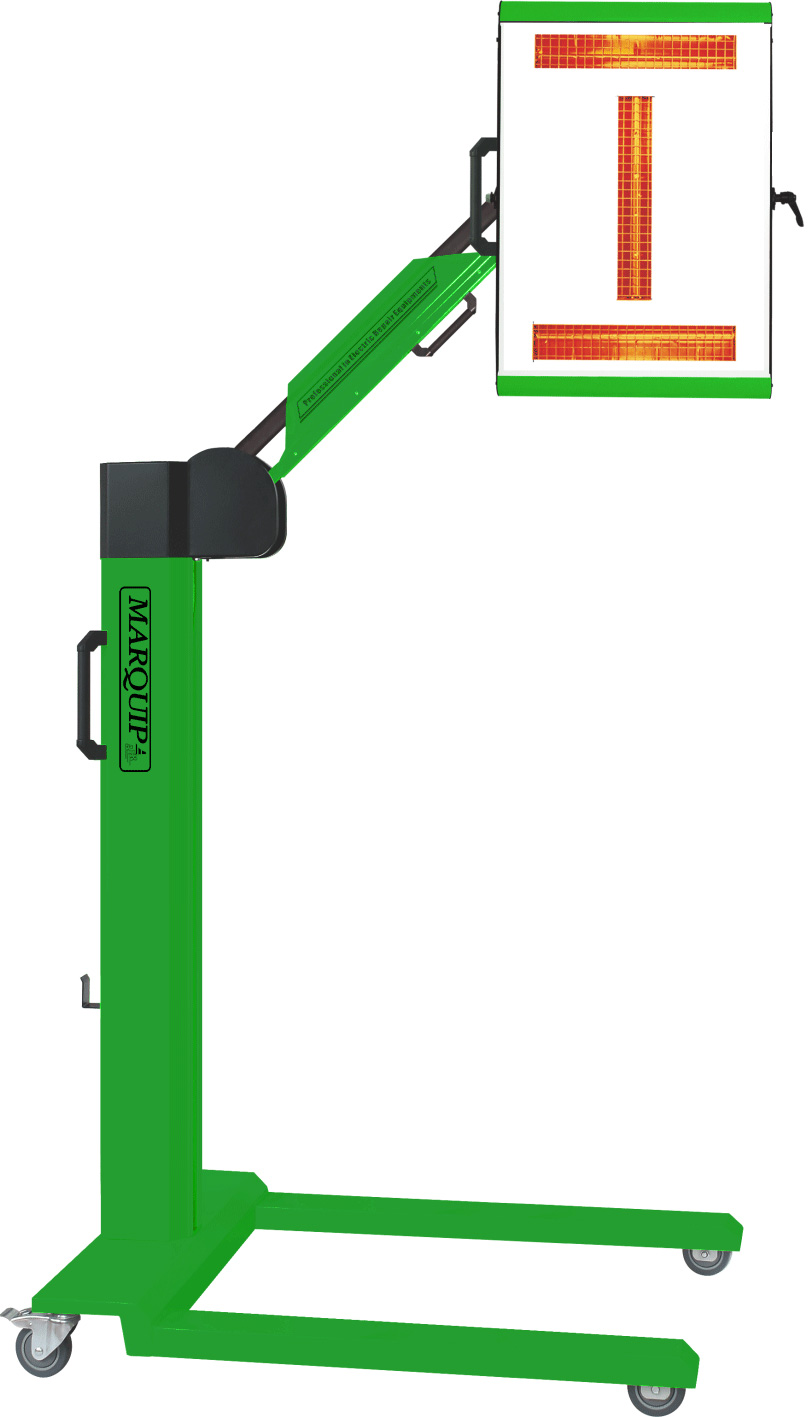

Curing primer/clearcoat spot repairs with short wave Infra-Red curing technology is one of the fastest ways to cure modern 2k automotive coatings.

Note: Always follow the IR manufactures recommendation for curing distances and times.

An IR unit can be a painter's best friend!

It is important to remember that modern 2k isocyanate catalysed automotive coatings from primers to clearcoats require temperature to activate and speed up the curing process, this is called “crosslinking” a chemical reaction which happens between the hardener and the binders within the coating.

The higher the temp e.g. 50-60°C the faster the crosslinking/curing process. However, when temperature falls below 10°C this chemical crosslinking STOPS the coating will dry because the solvents evaporate, but the coating will stay soft and uncured.

Note: under-cured primer IS a major cause of many paintshop issues resulting in expensive unplanned re-dos.$$$

Cure Types Explained

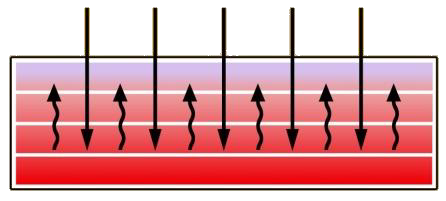

IR short-wave cure penetrates the entire coating, heating right through to the underlying substrate before coming back up, a full cure can be achieved in as little as 10-12 minutes.

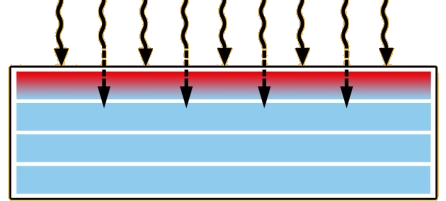

Conventional long-wave cure, e.g. a Spray bake oven on a bake cycle, creates a partial cure from the top-down, paint coatings can there after take several weeks to “fully cure” on their own.

Short Wave IR is a much more efficient way of curing modern automotive coatings.

A 2-way cure is superior to the top-down process associated with other heated curing methods in that it produces a more thorough cure and more heat can be applied without fear of skinning and solvent popping.

An IR unit is an invaluable tool to speed up process and reduce re-work.

Elevate

For customized SOP style documents ask DBNZ to do an ELEVATE version for your paint shop.

This incorporates the products and equipment that are used in your shop to create best practice as set by product TDS, Shop Owners and Paint Shop staff.

This will help to bring the understanding of what standards of repair are to be expected by all parties within the repair process, limit down time and speed up process.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #15Size: 265.13 KB | File Format: .pdf