#16 - DeBeer 1-380 1K UV Primer

Speed, Speed, Speed

Is the speed of cure of the primer layer of small to medium sized repairs crucial to the production output of your shop??

If YES, then there is currently nothing faster in the Refinish world than UVA Cured Primers.

Fully Cured Primer in as little as 3-5 min

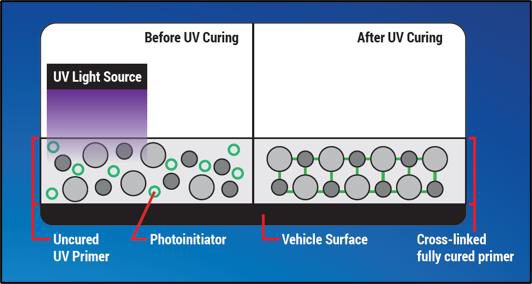

UV curing (ultraviolet curing) is the process by which ultraviolet light initiates a photochemical reaction that generates a cross-linked network of polymers through "radical polymerization" forming a near instant hard and durable coating.

The "UV Light Source" in the graphic above is light cure only - no heat is involved.

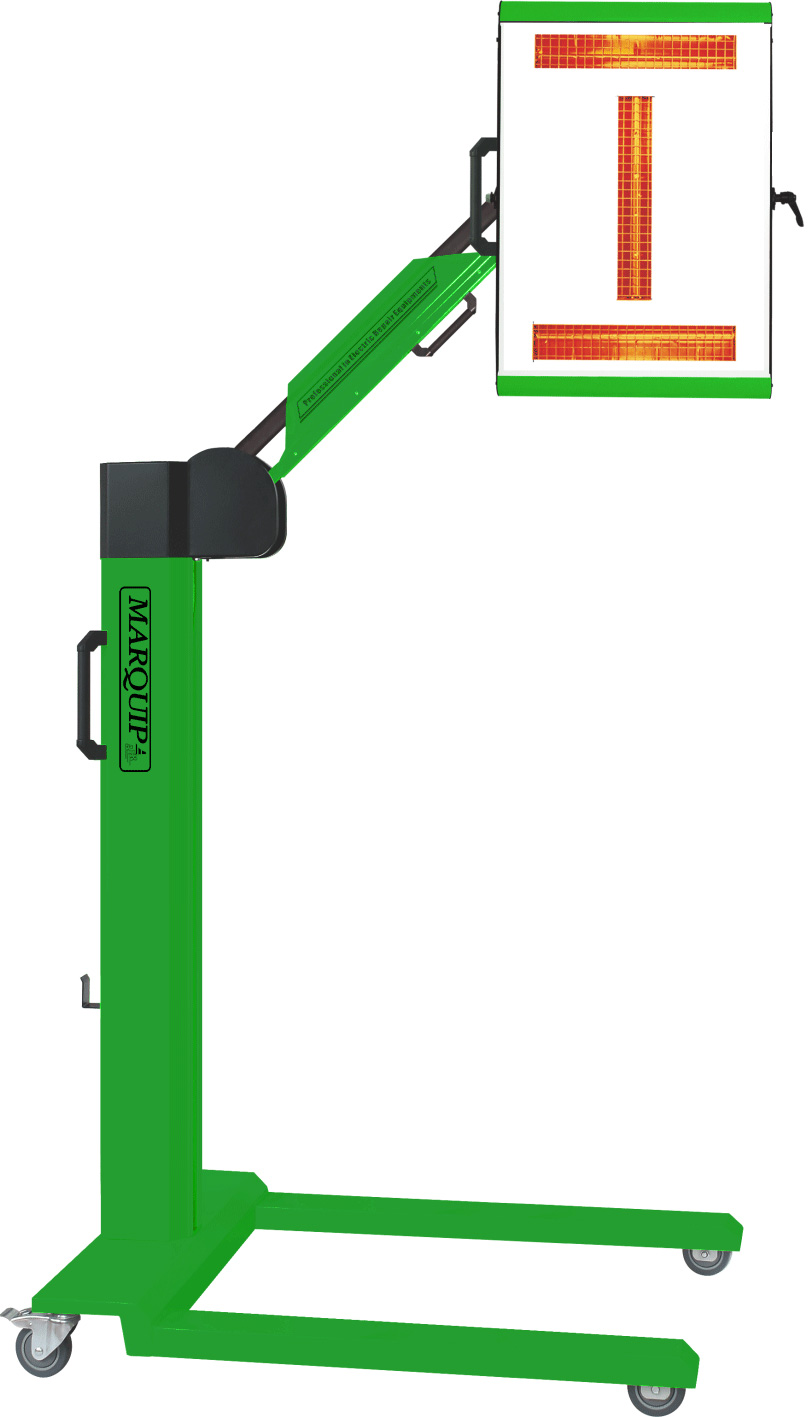

Note: Always follow the IR manufactures recommendation for curing distances and times.

A UV unit is an invaluable tool to speed up process and reduce re-work.

DeBeer 1-380 1K UV Primer

The 1-380 UV Primer is a single component UV primer that can be used on most automotive substrates.

Ready-to-use primer that completely removes the need for mixing. It has excellent filling and levelling properties that ensure a smooth and consistent fill every time. The primer has an accelerated drying time, curing in just 90 seconds with no further wiping needed. It's incredibly versatile primer that can be applied to common automotive substrates including plastics, e-coat, steel and galvanised steel.

DeBeer 1-380 1K UV Primer Benefits:

- Creates a smooth and consistent fill every time.

- Accelerated curing in just 90 seconds.

- Ready to use removing the need for complex mixing.

- Filling and levelling properties.

- Super fast curing.

- Single component primer.

The 1L tin is a much better economical option, as well as providing more control than that of an aerosol.

Elevate

For customized SOP style documents ask DBNZ to do an ELEVATE version for your paint shop.

This incorporates the products and equipment that are used in your shop to create best practice as set by product TDS, Shop Owners and Paint Shop staff.

This will help to bring the understanding of what standards of repair are to be expected by all parties within the repair process, limit down time and speed up process.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #16Size: 297.65 KB | File Format: .pdf