#19 - Delamination

Delamination / Poor Adhesion on Plastic Parts

Poor adhesion of a paint system to plastic parts can happen immediately or over time.

Most modern automotive plastics are designed to be painted. However, due to mould release agents used during the manufacturing process, new plastic parts will be coated with these agents on their surface, as well as often within the pores of the plastic itself.

It is therefore crucial that these agents are removed before any paint is applied, then a PLASTIC ADHESION PRIMER must be used.

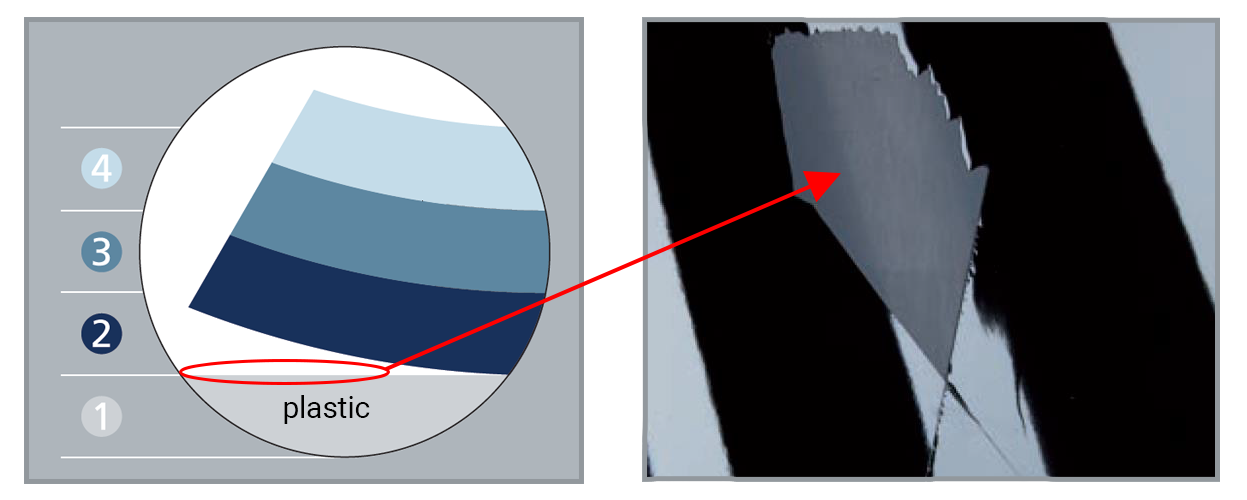

The example above shows an example of contamination / lack of adhesion with potentially no adhesion primer.

Caused by:

- Improper or insufficient cleaning of the plastic part, resulting in mould-release agents still being present (note: some plastics need tempering).

- Unsuitable primer or no primer used.

- Incorrect paint system selected.

Prevention:

- Temper plastic parts (e.g. bumper bars) before cleaning and sanding.

- Clean and degrease properly using 1-851 Antistatic Degreaser (or similar), 1-951 Wax and Grease remover (or similar), then soapy water.

- Use a plastic primer on all raw plastic, 1-60 Plastic Primer.

- Select recommended paint system for the substrate.

- Respect flash-off times (check TDS).

Remedy:

- Remove the affected paint system (pressure wash/steam clean).

- Temper, degrease and clean, build up paint system with correct products.

Contact your DeBeer Representative for further information.

Elevate

For customized SOP style documents ask DBNZ to do an ELEVATE version for your paint shop.

This incorporates the products and equipment that are used in your shop to create best practice as set by product TDS, Shop Owners and Paint Shop staff.

This will help to bring the understanding of what standards of repair are to be expected by all parties within the repair process, limit down time and speed up process.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #19Size: 225.58 KB | File Format: .pdf