#17 - Mottling

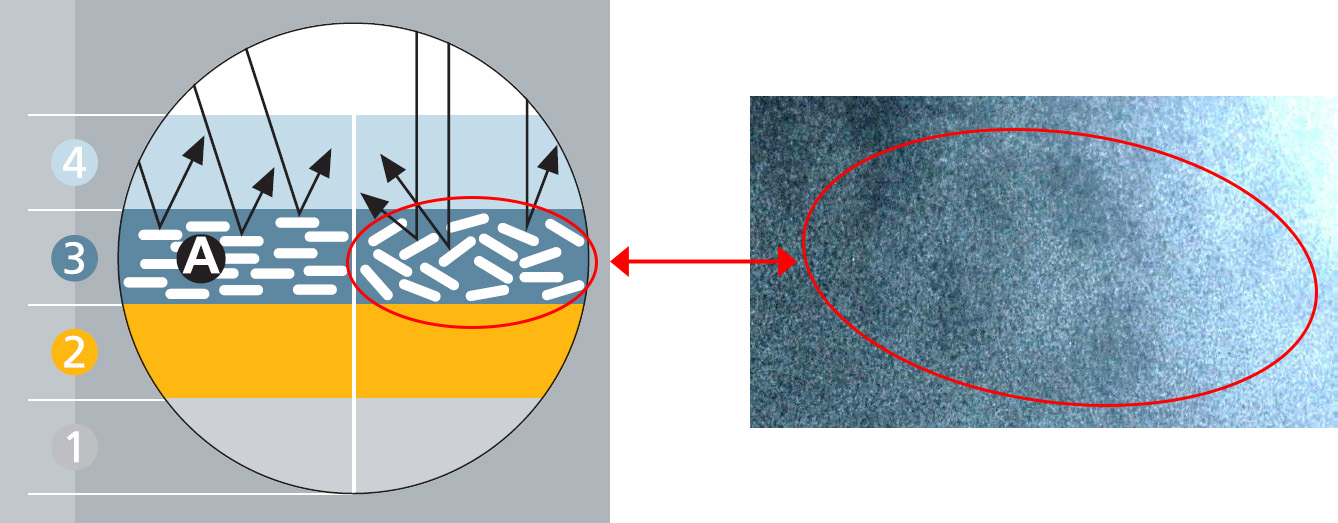

Mottling is seen in metallic and pearl effect colours. It's an uneven spreading (or laydown) of the colours effect pigments causing a visual disturbance, resulting in "mottled" or "blotchy" appearance as shown in the image below.

The effect pigments have not been allowed enough time to flow and lay as they should, resulting in an uneven visual appearance.

Caused by:

- Inappropriately fast thinner selected (fast evaporation).

- Unsuitable thinner for the product.

- Incorrect spraygun setup and/or incorrect air pressure applied.

- Basecoat is too heavy.

- Flash-off time are too short.

- Poor overlaps / too many coats.

Prevention:

- Select the correct thinner based on temperature, repair size and airflow.

- Only select the recommended thinner from the products technical data sheet.

- Use the appropriate gun set up and air pressure.

- Observe correct flash-off times.

- Use the correct spray technique.

Remedy:

Sand the clearcoated substrate with P500-800 dry, then respray based upon above recommendations, and if required use a slower speed thinner.

Elevate

For customized SOP style documents ask DBNZ to do an ELEVATE version for your paint shop.

This incorporates the products and equipment that are used in your shop to create best practice as set by product TDS, Shop Owners and Paint Shop staff.

This will help to bring the understanding of what standards of repair are to be expected by all parties within the repair process, limit down time and speed up process.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #17Size: 248.83 KB | File Format: .pdf