#25 - Solvent Popping

Solvent Entrapment/Solvent Pops

A very common painting issue is solvent popping or blistering, caused by solvent becoming trapped by the drying paint film.

Solvents are primarily designed to:

- Reduce the viscosity of the paint to allow it to be applied.

- Stay within the wet paint long enough to allow the coating to flow and lay down correctly.

- Pull resin and binders down to the substrate to help create adhesion.

Once they have completed these tasks, solvents MUST THEN EVAPORATE, all the way back up through the paint film to the surface, escape and leave the coating (allowing it to cure correctly).

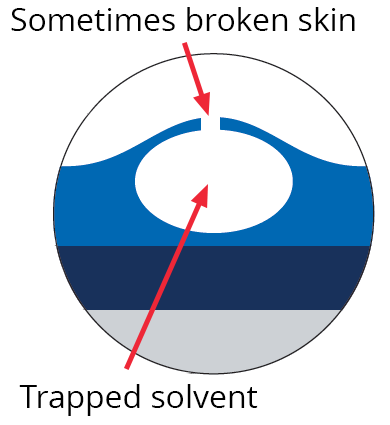

Failure to do this results in a skin forming on the surface of the coating before the solvents have had sufficient time to evaporate.

The escaping (trying to) solvent can then cause blisters, some of which will pop, but the skinned paint won't flow and close, these will leave behind open holes like "pinpricks".

This is Solvent Entrapment/Blistering and Solvent Popping.

Common Causes:

- Incorrect thinner used.

- Too heavy an application.

- Too large a gun set-up.

- Too short a flash-times between coats.

- Force dried too soon.

- A combination of the above.

How to Avoid:

- Use the products correct solvent in relation to the size of the job and temperature range.

- Use a gun with the correct nozzle set-up for the product.

- Observe the products recommended FLASH TIMES, apply with correct application technique.

Tip: if unsure, refer to the product TDS for more detail.

Elevate

For customized SOP style documents ask DBNZ to do an ELEVATE version for your paint shop.

This incorporates the products and equipment that are used in your shop to create best practice as set by product TDS, Shop Owners and Paint Shop staff.

This will help to bring the understanding of what standards of repair are to be expected by all parties within the repair process, limit down time and speed up process.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #25Size: 237.40 KB | File Format: .pdf