#8 - Cross-Contamination

Why You Shouldn't Use Just Any Old Solvent to Clean Spray Equipment

Using the wrong solvent to clean professional spray-painting equipment (especially pressure pot fluid lines) can lead to serious cross-contamination, which in turn can cause a poor finish quality during your next application.

This is an important, overlooked and often abused process, and yet can cause a lot of issues across all types of paint, especially when going through paint lines.

Cross-Contamination: A Common but Costly Mistake

If leftover residue from one type of paint isn't properly dissolved and flushed out, it can mix with a different paint system, the next time you spray.

Even trace amounts can cause:

- Poor adhesion.

- Surface defects (fisheyes, craters, wrinkling).

- Colour inconsistency.

- Spit grit and residue.

- Clog inline filters.

- Premature paint failure.

Incompatible Solvents:

If the solvent is not a direct match for the type of paint being flushed (e.g., trying to use a mineral sprit on a 2k epoxy), it will not dissolve all the paint components, this will leave behind unwanted paint residue within the hose.

Improper Flushing Technique:

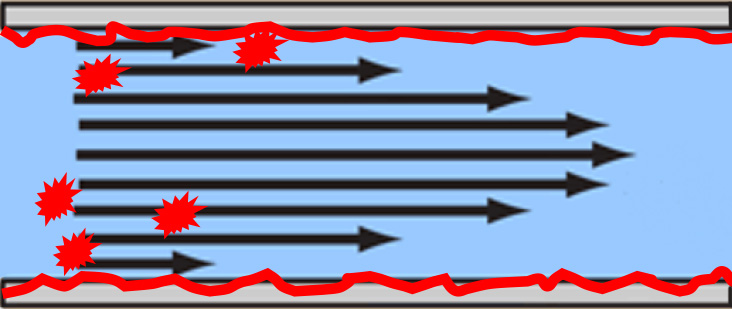

The most common cleaning error is simply pushing solvent through the line. This creates a LAMINAR FLOW where solvent moves faster in the center of the hose and slower along the edges, potentially leaving paint residue on the inner walls of the hose.

Laminar flow with incompatible solvent, leaving unwanted paint residue on the inner walls of the hose.

This residue can break away with the next application of paint which can clog filters, spit grit, or contaminate the next job.

How to Avoid

- Always clean with the solvent recommended by the paint manufacturer.

- Flush thoroughly between different types of paints.

- Avoid general-purpose solvents/gun-wash unless you're sure its suitable for your specific paint and equipment.

...The cost of using the correct solvent fades in comparison to replacing fluid lines or reworking jobs.

Consider...

Cutting corners with cleanup might save time or money in the moment—but the risk of contaminating your next job could cost you far more in rework, wasted product, or damaged reputation.

Lower quality thinners can leave behind a residue or have a higher water content, which can interfere with the paints drying, curing, or cleaning ability.

Particulate matter found in recycled or low-grade thinners can contaminate and clog expensive paint equipment.

Reputable manufactures use strict quality control measures in the manufacturing of their solvent blends to minimize these issues.

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #8Size: 236.52 KB | File Format: .pdf